Quality

since 1904

Natural

fuel.

If there is anything that has marked the history of UNION fireplace briquettes, it's time. For it is not only the time that briquettes give you in front of an open fireplace or stove that marks the tradition-rich brand. And every tradition needs time.

So, why not light up a cosy open fire, put on a few UNION fireplace briquettes and lean back? For this story started a long time ago.

- 20 million years ago

- 1790

- 1877

- 1900

- 1904

- 1945

- Today

20 million years ago

The power of Nature stemming from plants and organic (mineral) matter.

The Rhenish lignite-mining area – where UNION fireplace briquettes have always been made – looked completely different 20 million years ago. The climate was subtropical and moisty and the region was swampy and densely wooded. Where we find Cologne cathedral today there once stood other heavyweights like mastodons and mammoth trees way back then.

Roughly at that time, a process started that kept repeating itself and eventually led to the production of lignite. Plants and trees died, were decomposed into peat in moors and swampy waters by microorganisms and, over the centuries, towered up into layers several hundred meters thick. These layers were flooded, covered in sand, gravel and rocks and were overgrown again by plants. And the process started afresh.

Pressure turns peat into lignite.

The sediment layers and the new land mass that accumulated in the course of millions of years owing to earth-shifts, flooding and climate change exerted such pressure on the peat layers that they became compacted to form lignite.

Fireplace briquettes are concentrated solar energy.

The substance that turns lignite into such a high-performance energy carrier is carbon, so important for the entire eco-system. Due to the fact that lignite has come about from the remains of plants the carbon that has emerged from plants' photosynthesis is also conserved in fireplace briquettes. So, ultimately, it is solar energy millions and millions years old that is contained in lignite and, hence, in UNION fireplace briquettes, too, and makes briquettes a valuable energy source.

1790

When briquettes were still referred to as "Klütten" or clumps.

Ever since the end of the Middle Ages already, lignite has been mined in the Ville mountains between Bonn and Cologne. At the time this was called "Torff-Gräberei", or peat digging, since this combustible earth contained visible remains of wood and plants. From 1790 dates the first concrete information that peat digging had evolved in the course of time into a craft. "Klüttenbäcker" were people who mixed dried lignite with loam and water and air-dried it in large flowerpot-like vessels to form combustible "clumps".

1 March 1877

The first fireplace briquette is pressed in the Rhenish lignite-mining area.

The company that was then called "Actiengesellschaft Brühl-Godesberger Verein für Braunkohlenverwerthung" was the first to commission two Exter briquette presses – named after the inventor and patent holder of a peat press – and manufactured the first fireplace briquette in 1877. This paved the way for an industry that has greatly influenced the regional economy down to this very day.

1900

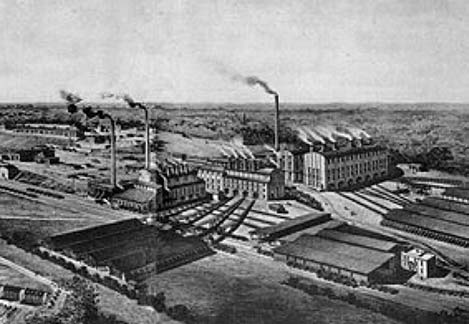

UNION is set up.

In the Rhenish lignite-mining area, many companies had settled in the meantime. Numerous coal fields, like Donatus, Fortuna or Rheingold, still resonate with many people even today. Technical progress in overburden excavators and briquette presses as well as increasing domestic demand had now turned the production of fireplace briquettes into a lucrative proposition.

1 April 1904

All pits are producing UNION briquettes.

It was still to take a few years until all of the mining area's pits joined the new brand. But, in 1904, things finally took off. As of that date, every company in the Rhenish lignite-mining area produced UNION briquettes. And that this was the right decision can also be seen in the longevity of the traditional brand that even today is among the long burners in open fireplaces.

Demand kept pace with the expansion of railway lines on the left bank of the Rhine. The rise in transport capacities, mass transportation that had now become possible and the lignite deposits that were largely deemed inexhaustible, all helped establish the new product as a low-cost alternative to hard coal.

1945

The UNION briquette as a means of payment and dispenser of warmth.

Only the older generation will still remember the tough post-War winter. A handcart full of briquettes at the time guaranteed warmth. And: it was possible to exchange "Klütten" for food on the black market.

After 2000

Quality and tradition are firm components of UNION briquettes.

Tradition is preserved progress, progress is continued tradition, as German physicist and philosopher Carl Friedrich von Weizsäcker (died 28.04.2007) put it.

UNION fireplace briquettes are still produced traditionally.

Manufacture – also referred to as upgrading – has not changed since 1904. Of course, the machines are computer-controlled by now. But the principle has remained the same: the coal is crushed and finely pulverized, then dried to evaporate its high moisture content.

At up to 1,000 bar pressure and without any added binders, the dried coal is then pressed in extruders into its characteristic form. An extrusion punch ensures that, on the front of a briquette, the classic UNION logo can be seen as a positive image and, on its back, as a negative.

Back to Nature.

Many exhausted pits in the Rhenish lignite-mining area have now been returned to Nature. They were reforested or converted into flooded gravel pits like Donatussee lake. And there we turn full circle – back to Nature.

Everything needs a bit of time, after all. Time that you can enjoy in front of your open fireplace or stove in a cosy atmosphere warmed by UNION fireplace briquettes.